Cooling tower selection guide

A cooling tower is a device that uses water to cool air or to take heat away from industrial equipment. A cooling tower is used to reduce the temperature of water, oil, acid, or any other fluid with a high specific heat capacity. According to how it works and what the body and parts are

A cooling tower is a device that uses water to cool air or to take heat away from industrial equipment. A cooling tower is used to reduce the temperature of water, oil, acid, or any other fluid with a high specific heat capacity. According to how it works and what the body and parts are made of, this system is one of the most important pieces of equipment in air conditioning.

How do cooling towers work?

The cooling tower consists of equipment with galvanized, wooden, concrete, and fiberglass bodies, sometimes individually and sometimes together with chillers, and with a variety of divisions including round, circular, and cubic, wet and dry, closed circuit, and open hybrid circuit, counterflow, crossflow, natural flow, and mechanical flow.

In short, the purpose of using this system is to cool the water.

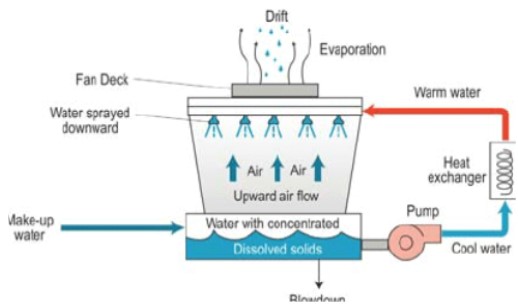

In industrial applications, cooling towers are used to cool water and cool air. In fact, its performance is similar to that of a water cooler. The water cooler by spraying water increases the air humidity and reduces the dry air temperature in summer. This system also causes a small part of the water to evaporate by spraying water and contacting the air, thus reducing the temperature of the water.

At this stage, at the same time as the water passes through the surface of the packing media, it comes into contact with the air, and part of the main water flow evaporates and enters the air.

In this way, the water entering the tower loses its temperature by passing through the packing of the cooling tower and surface evaporation (a heat-generating process) and enters the basin of the cooling tower with a temperature close to the wet temperature of the environment. Water moves through piping to cool systems that are overheated due to work, and water as a process fluid, being in the vicinity of these devices takes the excess heat of the equipment and moves to the cooling tower again.

As with what happened above, the cooling tower repeats itself until the employer either reaches a certain level of temperature or, in air conditioning systems, until 29 degrees Celsius is reached by the desired air and enters the chillers and fan coils.

History of cooling tower use

Over time, cooling systems have been designed and produced in various types, and the final system of this device has undergone many changes. The first generation of this device was officially introduced after the Great French Revolution as an atmospheric cooling tower or a man-made tower. These systems generally cooled the water by spraying the natural flow of water on the wood.

After a series of general changes, these systems were changed to concrete and large hyperbolic structures with a blower ventilation system were used under the name of concrete cooling towers. Due to the high construction costs, this model of the next generation was introduced under the name of galvanized towers.

- The body of this device was made of a hot galvanized sheet.

- The aeration system of this model was in the form of a centrifuge.

- They also had high energy consumption and production noise.

Due to deposition and corrosion and hard maintenance of the galvanized model, this model became obsolete like its competitors. So now very few manufacturers produce this model. The latest generation of this equipment is a fiberglass cooling tower with very low consumption and low noise axial fan system. If this model of cooling tower is produced and designed according to international standards, it will no longer have any of the limitations of the previous types of towers. The design of cooling towers has changed over time.

Cooling tower parts

Each cooling tower has parts and equipment that affect its correct operation and high efficiency. A cooling tower can work well and perform cooling operations with the help of its internal parts and components, and this equipment is different in each type and model of the tower. These parts are selected and installed on the tower based on the type of tower, its performance, its capacity, its installation location, and the customer’s budget.

most important cooling tower equipment:

- Body: The body is actually the supporting structure of all internal and external equipment. The body of the cooling tower consists of different parts. The body of the cooling tower causes the movement of airflow flow and the contact of the air with the water, and it supports the overall cover of the tower.

- Inner and lower skeleton or structure: This section is actually designed and used to strengthen the final strength of the cooling tower. In the lower part of the tower, a series of studs are used to divide and distribute the load on the foundation.

- Shaft: The shaft is responsible for transmitting power from the engine to the gearbox and is a pivot. This piece is generally made of steel or composite and is highly resistant to corrosion and breakage.

- Cooling tower fan or propeller: which with the rotation and power it takes from the electric motor causes the airflow to flow inside the tower. The fan is one of the main equipment of the cooling tower, which should be light and resistant to stress and hardness. Its material is usually made of steel, aluminum, plastic, fiberglass, and polyamide. The cooling tower fan is responsible for directing the air into the cooling tower.

- Fan stack: This has the role of guiding the airflow path and acts like a chimney that is placed in the upper part and gives the order to the outgoing air.

- Coil: Water from the system enters these coils and they give their heat to the cooling tower, which is sprayed on them by a water nozzle to cool them down. Because copper is a very strong conductor, coils are usually made of copper.

- Nozzle: It sprays the cool water in the cooling tower basin on the copper coils to take their heat and cool the hot water entering the system and turn it into cold water. The nozzle of the cooling tower, which is also called the sprinkler, is installed in the form of a thread in the water spraying system and is responsible for distributing and spreading water on the packings.

- Speed reduction system: This part is actually installed and designed by reducing the engine output speed and transferring the engine torque to the fan.

- Electric motor: This part is actually responsible for supplying the mechanical energy needed to rotate the fan and suck the air upwards. The engine power is generally calculated based on the volume flow rate of the tower and the diameter of the fan.

- Air intake valve: This part is actually responsible for supplying the intake of air.

- Cooling tower packing: The main and most important part of cooling tower parts is packing, which is also called heat exchange surfaces. This piece is responsible for increasing the heat transfer surface and thereby increasing the heat exchange rate.

Advantages of periodic service of the cooling tower and replacement of cooling tower parts

These benefits include:

- Reducing deposits and clogging of pipes

- Extending the life of internal parts

- Increase system efficiency

- Increasing the quality of outgoing water

- Reduction of production noise and vibration

- Reducing the temperature of the water leaving the cooling tower

Cooling tower applications

The cooling device is widely used in large industries of the country, refineries, and petrochemicals. They can also be used in the air conditioning systems of hospitals, residential, and office complexes.

Stay with DamaTajhiz mag for more information about cooling towers.

Types of cooling towers

There are different types of cooling towers that can be classified into two categories.

- Open circuit cooling tower: An open circuit cooling tower is a system that cools water by an open cycle (in terms of mass transfer).

- Closed circuit cooling tower: The operation of this tower is the same as the open circuit type. But with the difference is that in the open circuit cooling tower water has a direct connection with the air, but in this model, it has an indirect connection.

The price of the cooling tower

The price of the cooling tower is affected by various factors. Among the most important factors affecting the price of the cooling tower, we can point out whether the circuit is open or closed, the cooling capacity, and the material used in the construction of the body and internal equipment of the cooling tower.

In Iran, Damatajhiz is the first and most reliable specialized company in the field of building facilities equipment and all air conditioning devices since 2004, you can visit the site of this company to view the models, know the updated price and buy all types of cooling towers. This company also produces Damatajhiz cooling towers with the highest quality and variety and sells them at the best price and service. For more information, you can get advice from the experts of Damatajhiz Engineering and Manufacturing Company by dialing: 00982188822550 or texting Whatsapp at 00989034645254.

برچسب ها :

ناموجود- نظرات ارسال شده توسط شما، پس از تایید توسط مدیران سایت منتشر خواهد شد.

- نظراتی که حاوی تهمت یا افترا باشد منتشر نخواهد شد.

- نظراتی که به غیر از زبان فارسی یا غیر مرتبط با خبر باشد منتشر نخواهد شد.

ارسال نظر شما

مجموع نظرات : 0 در انتظار بررسی : 0 انتشار یافته : 0